Finishing Options

We offer a wide variety of print finishing options to add the final touch to your printed products. Choose from embossing/debossing,foiling, die-cutting and spot UV options to add extra detail to your project. Whether you’re looking for professional binding services or to add a decorative aspect to your piece, we have the right solution for you.

Foil stamping, (also known as foil application) typically a commercial printing process, is the application of metallic or pigmented foil on to a solid surface by application of a heated die onto foil, making it permanently adhere to the surface below leaving the design of the dye. adds a mirror-like finish to any image or text.

In the process known as hot foil stamping, foil stamping machines uses heat to transfer metallic foil to a solid surface. Examples of items that are foil stamped include annual reports, pocket folders, product packaging, note cards/thank you cards, business cards, envelopes and letterhead. The foil stamp is a permanent process.

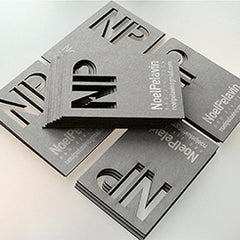

Die-Cutting is a process of creating sharp metal rules to cut shapes out of paper.Usually means that the printing staff is cut out with a “cookie cutter” to create the shape that you want the it to be.

Die cut may mean your printing staff will have rounded corners as opposed to square corners (which are often called “butt” or “kiss” cut).

Embossing and debossing are the processes of creating either raised or recessed relief images and designs in paper and other materials.Stamps an image, text or logo of your choice in relief, making it raised above the paper surface.

It creates an impactful aesthetic and adds a tactile dimension to your printed materials.An embossed pattern is raised against the background, while a debossed pattern is sunken into the surface of the material (but might protrude somewhat on the reverse, back side).

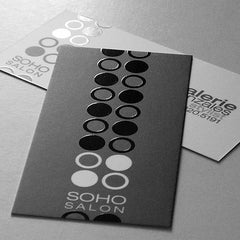

As the name suggests, a Spot UV coating or "varnish" is applied to chosen spots (areas), of a printed card.

This has the affect of highlighting and drawing attention to that part of the design, but it also provides the additional visual stimulus of having varied textures on a single printed surface.